Quasicrystal, heal thyself

Scientists have uncovered a remarkable self-healing property in a strange class of materials known as quasicrystals, revealing their ability to grow into a perfect, single structure even when faced with obstacles. The discovery challenges a long-held understanding of crystal formation and opens the door to creating large, strong materials free of defects for a new generation of applications.

Imagine you’re tiling a massive bathroom floor. You could use identical square tiles, laying them in a simple, repeating grid. This is analogous to a regular crystal. The pattern is predictable and repeats perfectly. When the arrangement of atoms repeats at fixed intervals, called periodicity, you have a conventional crystal.

But as you’re laying these tiles, you come across a pipe sticking out of the floor. To get around it, you would have to cut tiles into awkward shapes, breaking your perfect pattern. The lines where the mismatched tiles meet would also create a permanent scar on your floor. In the world of materials, these ‘scars’ are called defects or grain boundaries.

These defects are often the weakest points in a material, making it more prone to breaking or corrosion. Say you’ve a chair that’s starting to crack: the odds are the crack would’ve originated at a grain boundary. For many decades, a major goal for materials scientists has been to create large single crystals: materials with no grain boundaries and thus maximum strength and performance.

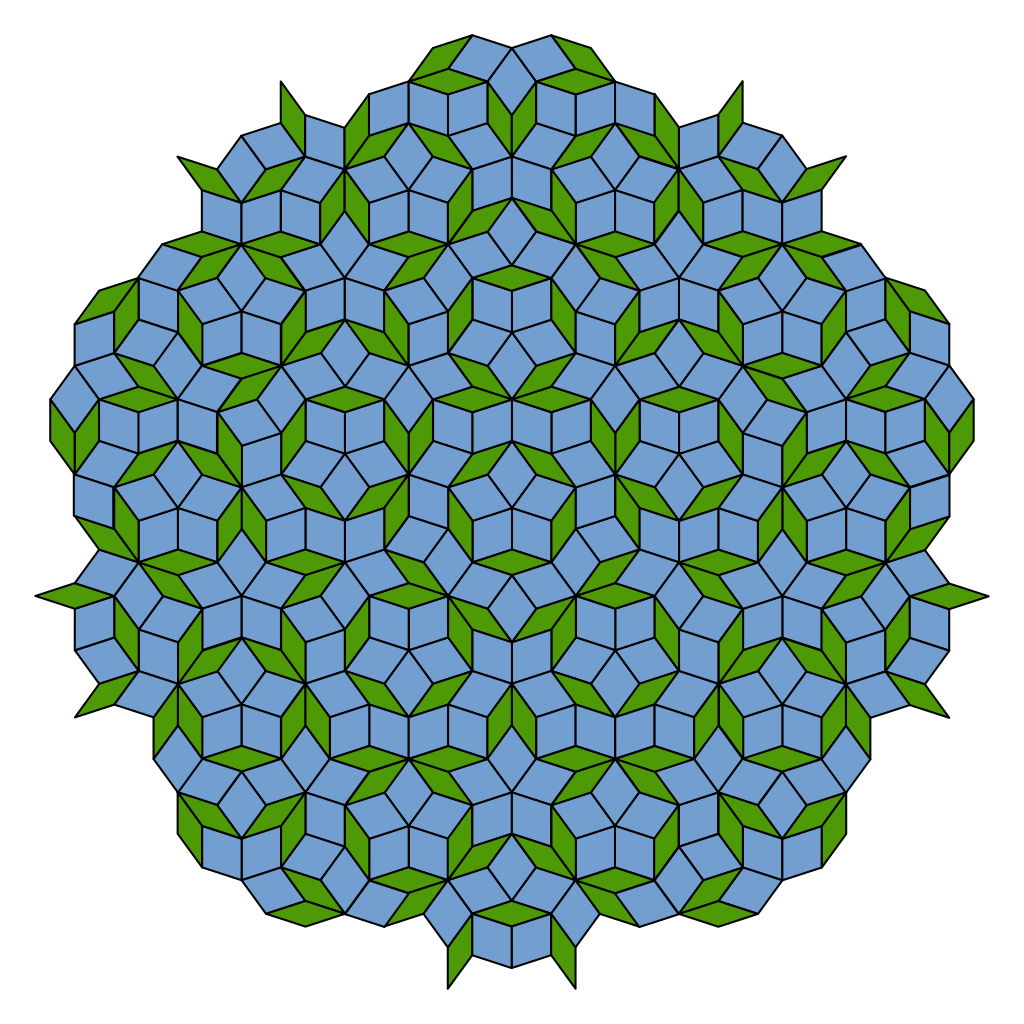

Now, what if instead of squares, you were tiling with a special set of tiles, say a mix of two different diamond shapes (see below). You could cover the entire floor without gaps, creating a pattern that looks ordered and intricate. But then you notice the catch: the pattern never exactly repeats. This is the essence of a quasicrystal. It has long-range order—its atoms are arranged in a pattern you can predict—but that pattern doesn’t repeat.

This fundamental difference led scientists to ask a critical question: what happens when a growing quasicrystal encounters an obstacle like that pipe in the floor? Does it also form messy, weakening defects or does its unique, more flexible structure give it a way to grow around the disruption and ‘fix’ itself on the other side?

In a new study in Physical Review Letters, researchers from the University of Michigan, Ann Arbor, hypothesised that quasicrystals possess a unique “self-healing” ability. They’ve written that this ability stems from special atomic rearrangements, known as phasons, that are only possible in quasicrystals. To test this, they decided to watch a specific type of quasicrystal, a decagonal quasicrystal, grow around a common, bubble-shaped obstacle found in metal alloys called shrinkage pores.

To watch this microscopic drama unfold, the researchers used a two-part strategy in which they combined a real-world experiment with a sophisticated computer simulation.

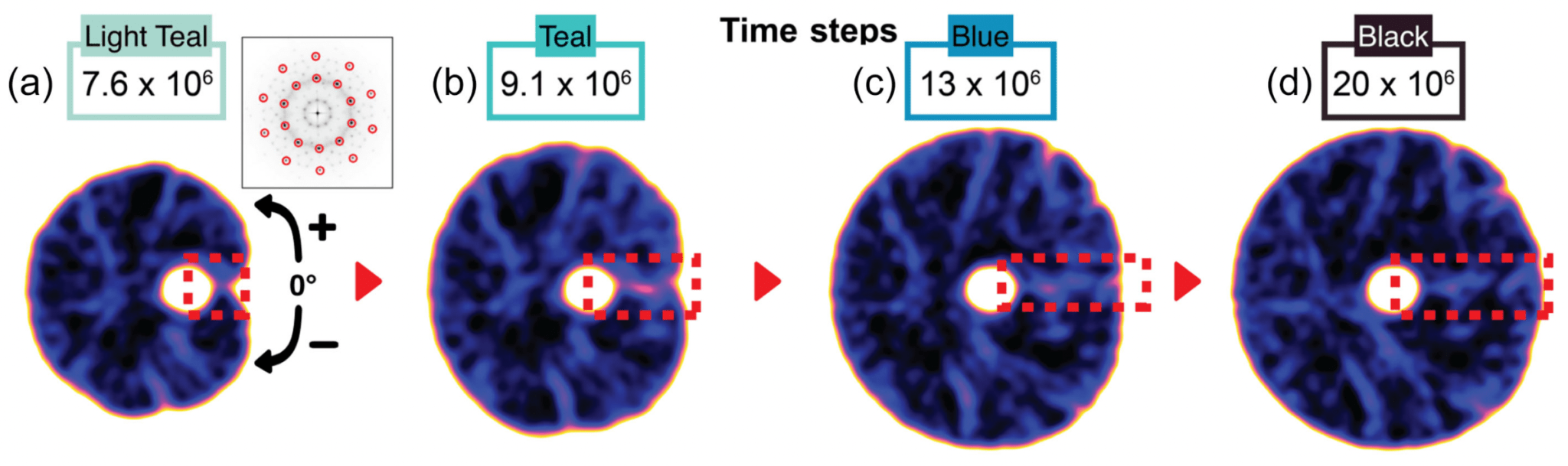

For the experiment, they used a technique called synchrotron X-ray microtomography. Think of it as a super-powered CT scan for materials. They took a small cylinder of an aluminium-cobalt-nickel alloy, melted it, and then carefully cooled it down. As the alloy solidified, quasicrystals began to form and grow, eventually running into the shrinkage pores that were already present in the material. The X-rays allowed the scientists to capture rapid, 3D “movies” of this process in real-time, tracking the crystal’s growth as it navigated the porous landscape.

To understand the atom-level mechanics behind what they were seeing, the team ran molecular dynamics simulations. This is like creating a virtual universe in a computer, where they could build a model quasicrystal atom by atom. They then programmed a virtual pore in its path and let the simulation run to watch exactly how the individual atoms rearranged themselves as the crystal grew and enveloped the obstacle.

The results were astonishing: both the live-action X-ray movies and the computer simulations showed the quasicrystal growing around the pores without forming any permanent defects.

As the growing front of the quasicrystal met a pore, it momentarily distorted its shape to flow around the void. Then when the two fronts met on the far side of the pore, they merged together perfectly. The crystal continued to grow as if the pore had never been there, resulting in a single, flawless quasicrystal that had simply swallowed the obstacle.

The key evidence from the experiments was the smoothness of the final quasicrystal’s surface. In a normal crystal, if a defect like a grain boundary had formed where the two fronts met, it would have created a permanent groove on the surface. The fact that the quasicrystal’s surface healed into a smooth, convex shape confirmed that no such defect was present.

The computer simulations revealed the secret to this ability: the phasons. A phason flip is one pattern of tiles changing into another without disrupting the overall order. When the growing crystal collided with the pore, it created localised stress. But through a cascade of these phason flips, the quasicrystal was able to distribute this stress and seamlessly stitch its structure back together. The scientists described this as an err-and-repair mechanism because the quasicrystal makes a temporary “mistake” at the collision point, then quickly corrects it. The result: perfect structure.

The finding has profound implications for materials science. First, it suggests that creating large, defect-free single crystals—currently a notoriously difficult and expensive process for conventional materials—could be dramatically easier with quasicrystals. Their built-in fault tolerance means they might be grown perfectly using simpler and cheaper methods.

The ability to easily create large, single-grain quasicrystals could also better unlock their incredible potential. Lacking the weak points of grain boundaries, quasicrystals could be used to create exceptionally strong, hard, and lightweight alloys for aerospace and industrial applications. Their unique structure also gives them interesting properties like low friction and low adhesion, making them ideal as durable nonstick coating.

The err-and-repair mechanism is also a form of self-healing at the most fundamental level. Understanding this process could inspire the design of a new class of “smart” materials. For instance, imagine a composite that when cracked or damaged can automatically absorb the defect and ‘repair’ its own atomic structure, maintaining its integrity and performance. The principles revealed in this study could be applied to other fields, such as creating more durable catalysts for the chemical industry that can resist degradation from internal pores.

Overall, this research reshapes our understanding of how ordered matter can form and provides a blueprint for a new generation of resilient materials built from the atom up.